Machine Features

2024 version

Machine working vedio:

one: Machine is suitable for PVC PET material cylinder curling.

two: Machine using the hydraulic system with more stable working. is fast and accurate.

three: One machine can product different size products.

four: Servo motor speed adjusting by needed.

five: Machine fast curling for PVC cylinder by electrical heating automatic.

Machine parameter

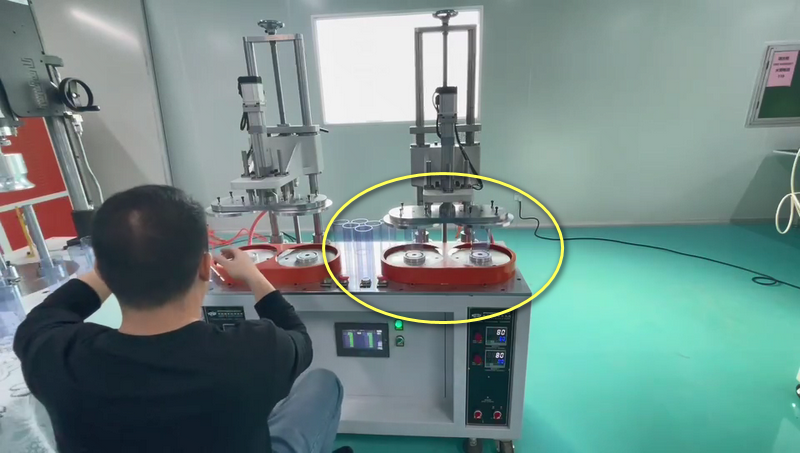

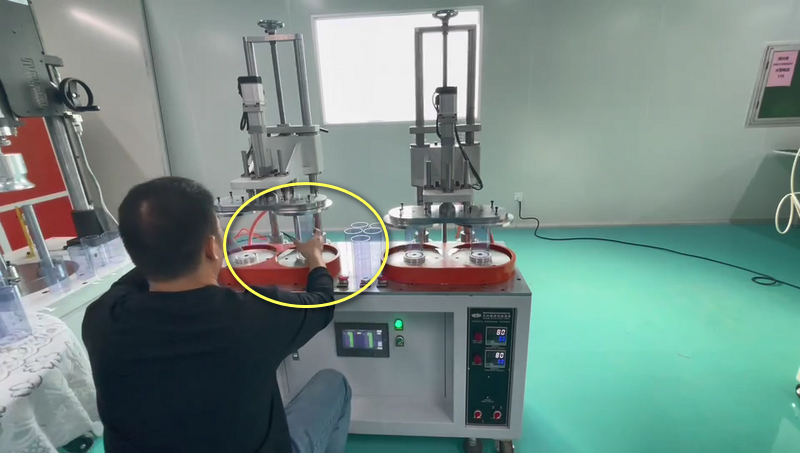

Machine working details:

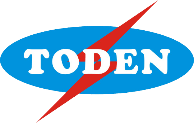

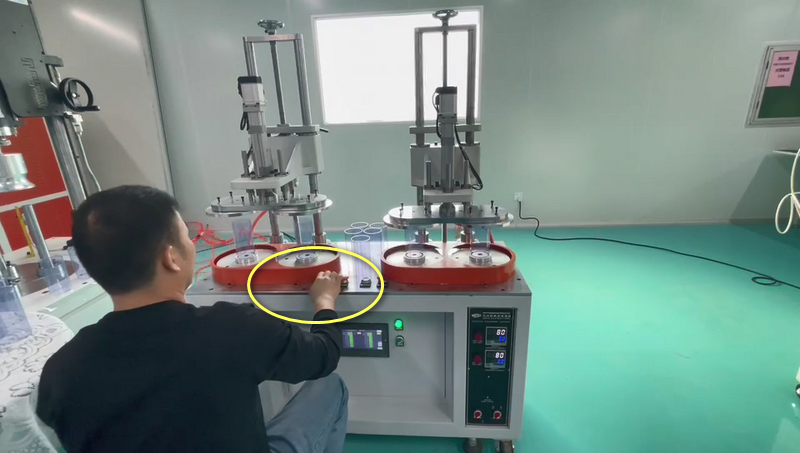

1.Manual putting Round cylinder box on the curling mold.

2.Touch"start" ,machine up head going down ,and press the cylinder

3. Cylinder box edge will curled by down pressure.

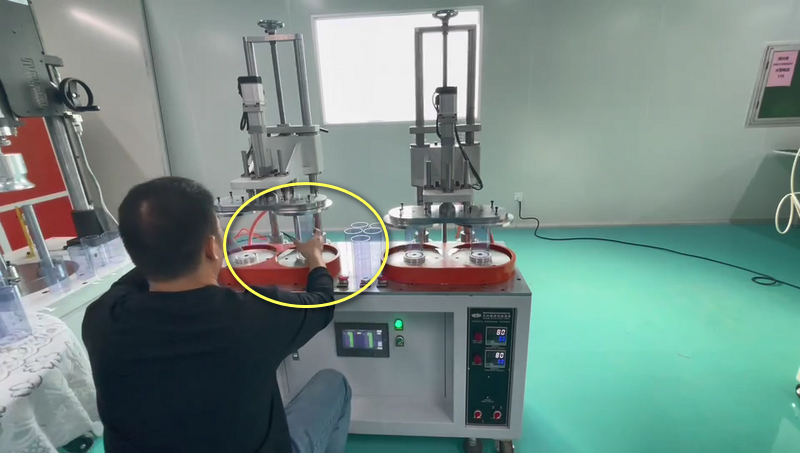

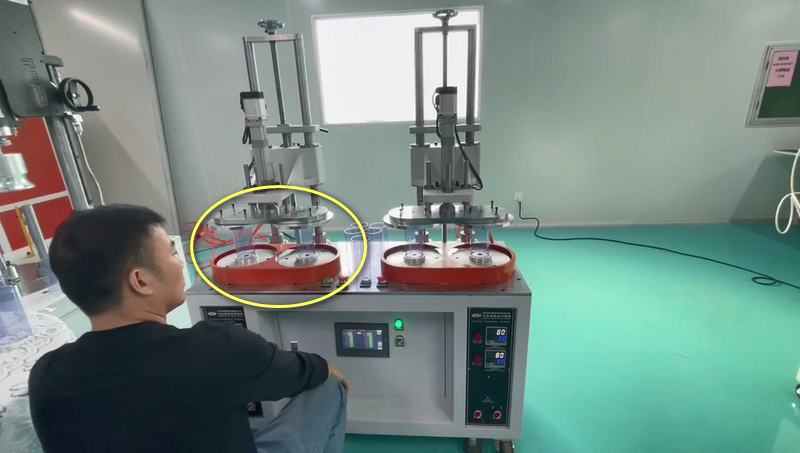

4.after some time, the curled cylinder box finished.

5.Than going to another two-working station . To curling the other side of the cylinder boxes. the same way.

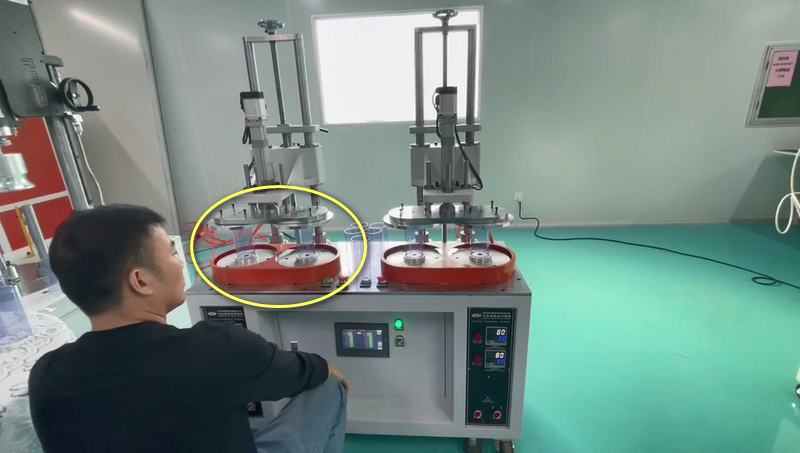

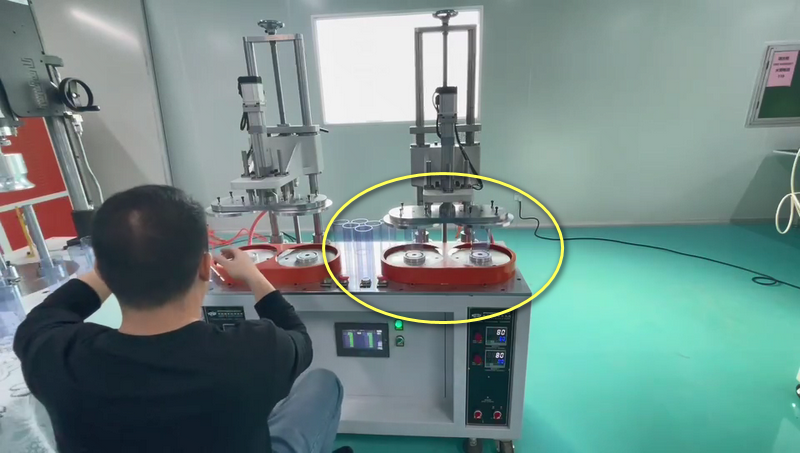

6.Putting the one-side curled cylinder boxes ,of course the height of cylinder boxes is shorter than the original one.

7. both side curled is for cover and bottom welding .for bottom welding ,only need curling 90 degree ,and for cover ,it need curling 120 degree.

8. customer feedback:

Customization Process

-

Inquire

-

Sample

-

Quote

-

Confirm

-

Contact

-

Produce

-

Ship

-

After-sale