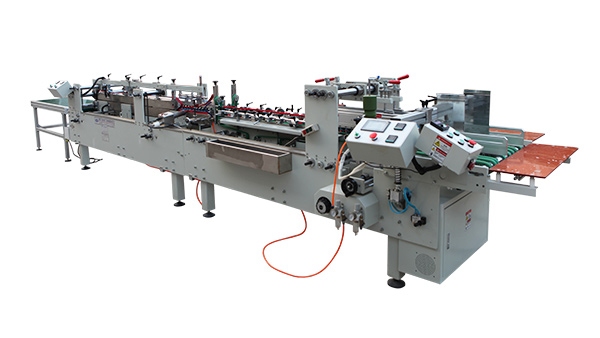

PET Roll soft line crease and die cut machine

Model:AT-14

Machine Features

Machine working vedio

1: Roll material-- Flatten--Crease and die cut --sheet cutter-- stack.

2: Suitable material: PVC APET PETG GAG rolls material.

3: Heating by oil and electric, Stable and save power.

4: HF heat die cut, the suitable soft line without any white or broken.

5: Mould made by normal wooden board with cutter, not special material mould.

6: 100% connect with working board without any medium.

7: Plastic Boxes line will not break.

8: Ensuring save worker source, Double-roller loading for automatic production.

Machine parameter

Machine working vedio

Plastic boxes crease and die cut Machine Working Process:

1. PVC PET roll material loading ,Roll paper core ID is 74 mm, max weight is about 100kg .two roll loading for continues working .

![IMG_8361[00_00_02][20200731-111138] IMG_8361[00_00_02][20200731-111138]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_2.png)

2. Heating Cylinder function is flatten the material .it is suitable for PVC PET material , 0.18-0.6 mm thickness.

![IMG_8361[00_00_10][20200731-111212] IMG_8361[00_00_10][20200731-111212]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_4.png)

3. Putting Protection film ,one side putting protection film ,Using PE Film in case of Scratch.

4. Die cutting table size:700*500 mm.

![IMG_8361[00_00_15][20200731-111226] IMG_8361[00_00_15][20200731-111226]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_6.png)

5.Cutter in the end. cutting into pieces of material .

![IMG_8361[00_01_45][20200731-111510] IMG_8361[00_01_45][20200731-111510]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_8.png)

6. Machine with the high frequency system ,To making the plastic boxes line soft ,easy folding ,no break.

![IMG_8361[00_01_13][20200731-111411] IMG_8361[00_01_13][20200731-111411]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_10.png)

Customization Process

-

Inquire

-

Sample

-

Quote

-

Confirm

-

Contact

-

Produce

-

Ship

-

After-sale

![IMG_8361[00_00_02][20200731-111138] IMG_8361[00_00_02][20200731-111138]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_2.png)

![IMG_8361[00_00_10][20200731-111212] IMG_8361[00_00_10][20200731-111212]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_4.png)

![IMG_8361[00_00_15][20200731-111226] IMG_8361[00_00_15][20200731-111226]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_6.png)

![IMG_8361[00_01_45][20200731-111510] IMG_8361[00_01_45][20200731-111510]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_8.png)

![IMG_8361[00_01_13][20200731-111411] IMG_8361[00_01_13][20200731-111411]](/resource/images/d508158a5e4e476987c4a376dc57f7fa_10.png)